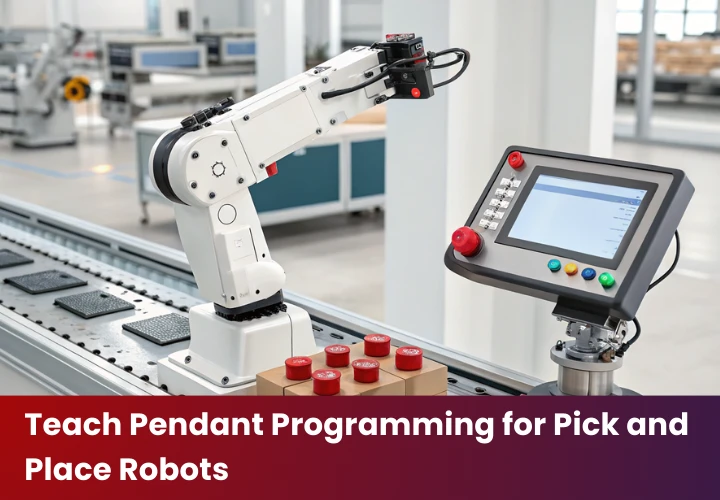

In the world of industrial automation, pick and place robots are the unsung heroes. These tireless machines are the backbone of modern manufacturing, performing millions of repetitive tasks with superhuman speed and precision. But how do we guide these powerful arms to where they need to go and what they need to do? The answer often lies in a rugged, handheld device: the teach pendant.

While new methods like offline simulation and AI-driven programming are emerging, teach pendant programming remains the most fundamental and widely used technique for instructing industrial robots. Understanding how to use one is an essential skill for any robotics technician, engineer, or operator.

This comprehensive guide will walk you through everything you need to know about teach pendant programming, specifically for the most common application: pick and place robots.

What is a Teach Pendant?

A teach pendant is a handheld control unit that allows you to directly interact with a robotic arm. Think of it as the robot’s remote control, but far more sophisticated. It typically features a large screen, a joystick or directional buttons, a keypad, and crucially, an Emergency Stop (E-Stop) button.

This device connects directly to the robot controller—the robot’s brain. Using the pendant, an operator can:

- Manually move the robot arm to specific positions (a process called “jogging”).

- Record these positions as points in a program.

- Define the type of motion the robot should use to move between points.

- Control the robot’s end-effector (like a gripper or suction cup).

- Test, edit, and run the robot’s program.

Essentially, you “teach” the robot a sequence of movements by physically guiding it through the steps and recording them. This direct, hands-on approach is why it’s a go-to method for many applications.

Why It’s Perfect for Pick and Place Robots

The core function of a pick and place robot is to move from Point A (Pick) to Point B (Place) with high accuracy, over and over again. Teach pendant programming is exceptionally well-suited for this task for several key reasons:

- Physical Accuracy: For a pick and place task, the robot’s gripper must align perfectly with the object. With a teach pendant, the operator is right there, visually guiding the robot’s final millimetres of movement to ensure the ‘pick’ position is exact. This real-world precision is difficult to achieve in a purely virtual environment.

- Simplicity for Linear Tasks: Most pick and place operations are a simple, repetitive sequence: Move to Pick -> Grip -> Move to Place -> Release. This straightforward logic is easy to create by recording a handful of points, making the teach pendant an efficient tool for the job.

- Quick On-the-Fly Adjustments: Manufacturing lines are rarely static. If a part feeder shifts slightly or a new box size is introduced, an operator can quickly use the teach pendant to touch up the program points without needing to go back to a computer, recompile code, or run complex simulations. This minimizes downtime and keeps production running smoothly.

How to Program a Pick and Place Robot: A Step-by-Step Guide

While the specific interface varies between brands like FANUC, KUKA, or Universal Robots, the fundamental process of programming a pick and place robot with a teach pendant is universal.

Step 1: Safety First!

Before moving the robot, ensure all safety protocols are followed. Clear the robot’s work area (cell), make sure all safety gates are closed, and always know where the E-Stop button is. When you’re first creating a program, run it at a very low speed (10% or less).

Step 2: Set the Tool Centre Point (TCP)

The TCP is the “tip” of your tool. For a pick and place robot, it’s the very center of the gripper’s fingers or the middle of a suction cup. Defining an accurate TCP is critical. If the TCP is wrong, the robot will pivot incorrectly, and all its programmed points will be inaccurate. Most systems have a built-in wizard to help you define the TCP by touching a single point from multiple angles.

Step 3: “Jogging” the Robot into Position

“Jogging” is the manual movement of the robot. You’ll use the pendant’s joystick or buttons to move the arm. There are several coordinate systems you can use:

- Joint Mode: Moves one specific joint (axis) of the robot at a time. Useful for large, sweeping movements.

- World/Cartesian Mode: Moves the TCP along a straight X, Y, or Z-axis relative to the robot’s base. This is essential for precisely aligning the gripper with a part.

Step 4: Recording the Key Points

Here’s a typical point sequence for a basic pick and place task:

- Home Position: A safe, neutral starting and ending point. Jog the robot here and record P1 (Point 1).

- Approach to Pick: A point a few centimeters directly above the object to be picked. This prevents collisions. Jog the robot here and record P2.

- Pick Position: The exact location where the robot will grasp the object. Carefully jog the robot down to this spot and record P3.

- Add Gripper Command: After P3, insert a command to “Close Gripper” or “Turn on Vacuum.”

- Retract from Pick: This is often the same as the approach point (P2). Record this as P4.

- Approach to Place: A point a few centimeters above where the object will be placed. Jog the robot here and record P5.

- Place Position: The exact location for placing the object. Jog to the final destination and record P6.

- Add Release Command: After P6, insert a command to “Open Gripper” or “Turn off Vacuum.”

- Retract from Place: This is often the same as the place approach point (P5). Record this as P7. Finally, add a move back to the Home position (P1).

Step 5: Defining Motion Types

When you record a point, you also define how the robot moves to it. The most common types are:

- Joint Move: The fastest motion. Each robot joint moves independently to get to the endpoint. The path is not a straight line, so only use it for moving through open space (e.g., from Home to an Approach point).

- Linear Move: The robot’s TCP moves in a perfect straight line. This is slower but essential for precise movements, like moving straight down onto an object (from P2 to P3) or inserting a part.

Step 6: Test, Refine, and Run

Your program is now ready! Set the robot’s speed to low and run a single cycle. Watch carefully for any potential collisions or misalignments. Adjust any points as needed. Once you’re confident the program is safe and accurate, you can gradually increase the speed and put the robot into production mode.

Advantages vs. Disadvantages

Teach pendant programming is a powerful tool, but it’s important to understand its limitations.

The Bottom Line

For the vast majority of pick and place robot applications, teach pendant programming is—and will continue to be—the most practical and efficient method. It provides the hands-on control needed for precise positioning and allows for the rapid deployment and adjustment of simple, repetitive tasks.

While offline programming offers powerful simulation capabilities for complex assembly lines, the teach pendant remains the indispensable tool for the final, real-world setup. Mastering it is the first and most important step toward becoming an expert in robotic automation.