In this fast-changing manufacturing world, automation has become more of a necessity than a luxury. Top entry IML robots are among the greatest emergent technologies. Advancing the art of IML, these high-end machines are revolutionising the business by making processes more efficient, precise, and adaptable. This blog will discuss the characteristics, benefits, and potential applications of Top-Entry IML robots about their side-entry IML counterparts.

About

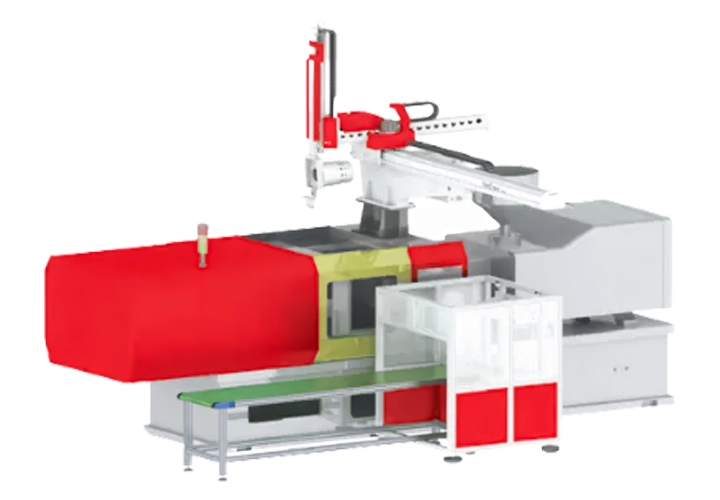

Top Entry IML Robots are specialised machines that automate labelling entry into molds using injection molding robotics. This procedure combines the labelling process with the whole production cycle, thus avoiding injection molding while the product is still raw. This makes the whole process much more effective and enhances the quality of the final product.

Top Entry IML Robots vs. Side Entry IML Robots

Those interested in automating IML production with an IML robot must decide on a side-entry or top-entry robot. Both have pros and cons.

- Top Entry IML Robots—The first advantage of these robots is that they are developed for applications where overhead access is best suited to allow for fast and efficient label loading into the molds. The machines have a vertically minimised footprint, making it quite easy to fit into production lines without the need for adjusting productions on their scales.

- Side Entry IML Robots—On the contrary, side entry IML robots generally need more floor space and show lower cycle time efficiency. They are also limited in their ability to create complex mold designs and less precise in label positioning.

Also check out: Benefits of Side Entry IML robots

Advantages of Top Entry IML Robots

Following are some of the main advantages that have spurred the growth of Top Entry IML Robots:

- Improved Efficiency: A top entry robot can integrate labelling with the molding cycle. This has resulted in an enormous saving of time in production where every second counts, particularly in high-volume manufacturing.

- Improved Accuracy: These IML robots feature superior vision and precision engineering. This results in labels being accurately seated within the mold.

- Space-Saving Design: Top-entry robots occupy less floor space than their side-entry counterparts. Compact production lines allow manufacturers to use more manufacturing space.

- Versatility and Flexibility: Top-entry robots easily adapt to different molds and labelling requirements, which is very useful for manufacturers of a wide range of products.

- Improved Security: Automation significantly reduces the probability of human error. An enclosed system minimises the possibility of contamination during the labelling process.

Technological Innovations in Top-Entry IML Robots

Some of the advanced technologies applicable to this equipment include:

- Advanced Vision Systems: High-resolution cameras with complex algorithms have ensured the accurate placement and alignment of labels, thus ensuring a higher accuracy of the label application.

- Machine Learning: The top-grade entrance In-mold labelling robots are now endowed with machine learning that senses production data to make real-time operational changes.

- Strong Software Integration: Modern IML robots are marked by user-friendly software that makes programming and operation easy and intuitive. The software can seamlessly integrate into other manufacturing systems, providing real-time data and analytics.

- Energy Efficiency: Better energy-efficient motors and drives save operational costs while reducing the process’s environmental footprint.

Industries Benefiting from Top-Entry IML Robots

As such, owing to the flexibility of Top Entry IML Robots, it can easily find applications in varied sectors. The main sectors where this technology can prove beneficial are:

- Consumer Goods: In-mold labelling robots are used by food, beverage, and household product manufacturers to achieve great quality point-of-sale labelling that stands out on shelves.

- Pharmaceutical: In pharmaceuticals, the precision and cleanliness offered by IML are important because the product has to be tamper-proof and thus safe.

- Automotive: In automotive, IML robots assist in designing strong yet good-looking auto parts to deliver better performance and looks

- Electronics: Precision IML provided by top entry robots ensures components are accurately labelled before assembly and compliance.

- Cosmetics: The cosmetic sector survives on branding; thereby, Top Entry IML Robots help make visually attractive packaging to ensure that consumers will be attracted to it, while at the same time, quality does not compromise.

Future of IML Automation with Top-Entry Robots

Future trends include:

- The best Top entry IML robots will be modified further to produce even greater levels of customisation so that short runs with different designs can be produced with the least downtime.

- AI-Driven Operations: AI can enhance robot efficiency like none other. These robots learn from past operations and can predict optimum performance settings.

- Sustainability Initiatives: As sustainability becomes increasingly important, designing IML robots may also involve minimising material waste and energy consumption.

Bottom Line

Top-entry IML Robots are the future of in-mold labelling automation. They perform better and more precisely and are highly versatile, which means they are superior to traditional labelling alternatives or side-entry options.