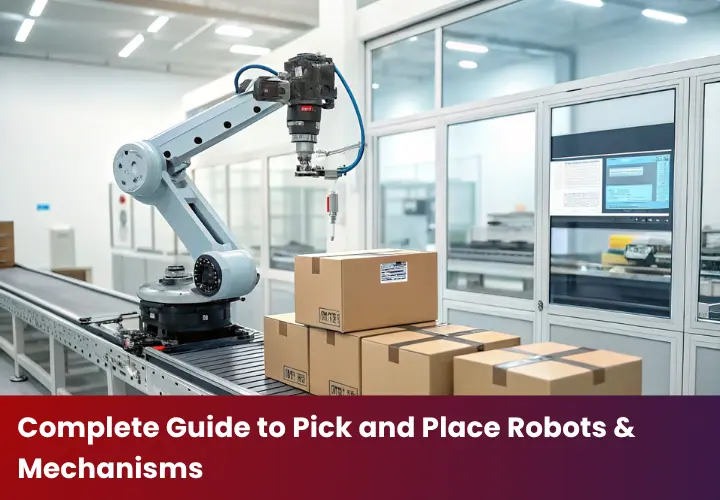

Factories hum. Conveyors rattle. Operators rush. Orders keep piling up. If you’ve ever stood on a shop floor during a busy shift, you’ll recognise the rhythm. Every part must go to its next station on time. That’s where pick and place robots come in, working like a diligent apprentice who never tires.

What Are Pick and Place Robots?

Pick and place robots do one thing really well: they grab an item and move it to a new spot. Imagine a super-reliable helper who never takes a lunch break. They can grip tiny electronic chips, heavy metal gears, fragile glass vials, or even spongy pastries. They do it all with quick hands and a steady touch.

There’s a reason so many companies lean on these machines. Labour can be unpredictable. Fatigue slows humans down. Mistakes slip in. Robots never blink or yawn.

Why Should You Care?

Let’s be honest. Speed matters. If you can get products out the door faster, you make more money. If you can cut down on damaged items, you make more money. Robots excel at this.

And it’s not just about money. Think about safety. Who wants to haul 50-pound parts up and down all day? A robotic arm can do the grunt work. People stay safe. Injuries drop. Everybody’s happier.

Core Features That Make a Difference

Pick and place robots aren’t all the same. Here’s what to look at before you buy one:

1. Rapid Movement

These machines hustle. A good one can cycle through motions in less than a second. That means hundreds or even thousands of repetitions per hour without tiring or losing focus.

2. Gentle Touch

Some items can’t take a beating. Ever seen a pastry smushed in its package? Bad news. Robots with gentle suction cups or soft grippers can hold fragile stuff without squashing it.

3. Spot-On Accuracy

You need parts placed in the same position every time. Imagine putting a puzzle together blindfolded. Robots don’t need to see — they already know where each part belongs.

4. Quick Changeovers

Production lines switch up all the time. A good pick and place robot should adapt with just a few tweaks. Maybe you’re boxing up phone cases this morning and assembling gearboxes after lunch. No problem.

5. Easy Control

Programming these machines shouldn’t feel like rocket science. Modern interfaces often use touchscreens and simple menus. Even a new hire can figure it out after a short demo.

Industries That Benefit

This tech pops up everywhere. Electronics companies use them to place tiny chips. Food companies use them to gently move baked goods. Automotive plants rely on them to lift parts too heavy for a person. The examples go on.

Each business is different, but the goals look the same: cut errors, trim waste, speed up work. That’s why these machines keep cropping up across factories of all sizes.

What Makes Pick and Place Robots Worth the Investment?

It’s easy to hesitate before spending money on automation. You may worry it will sit idle or be too hard to use. That’s a fair concern.

Here’s a simple thought: robots do exactly what you tell them. They don’t call in sick. They don’t skip steps. Once programmed, they just keep humming along. That’s why so many companies recover the investment faster than they expect.

And here’s a funny anecdote. One of our customers ran a bakery. Before robots, pastries went flying off the belt like clowns at a circus. Within a week of installing pick and place arms, their defect rate fell to almost zero. The owner kept joking that the robots “had more patience than his teenage kids.”

Do You Need a Pick and Place Robot?

Take a moment. Picture your busiest shift. Maybe it’s the holiday rush or the launch of a new product. What slows you down? Probably repetitive lifting, moving, and setting things in boxes.

That’s exactly where these machines shine. They slot into existing production lines like a missing puzzle piece. You can scale up without overworking your crew or skimping on quality.

And let’s talk about workers. They often appreciate automation. Why? Robots take on the boring stuff so humans can focus on creative tasks — fixing machines, improving processes, or chatting up customers.

Choosing the Right Pick and Place Robot

Here are a few practical questions to ask yourself before buying:

-

What weight does each part have? Robots come in different strengths.

-

How fast do you need to go? Speed is adjustable, so match the robot to your output.

-

Will your product change often? Pick a model that’s easy to reprogram.

-

Do you need to integrate with existing equipment? Many robots fit right into standard lines.

Answer those and you’ll make a solid choice.

Why Work with Delta Stark Engineering?

Picking the right automation partner matters as much as picking the right machine. Delta Stark Engineering gets this. Our team knows robots inside and out. We help you plan the setup, train your crew, and support you long after the sale.

Our clients appreciate the personal touch. We listen, then recommend a practical fit for your goals. We help you hit production targets without breaking the bank. And we stick around if you need tweaks or maintenance.

Pick and Place Robots in India

Manufacturers across India — from automotive giants to small food packers — are turning to pick and place robots to streamline their production. With rising demand for automation, companies here are leveraging these machines to tackle labour shortages, improve precision, and scale up quickly. Delta Stark Engineering supports businesses in India by providing solutions that fit local needs, including easy installation, operator training, and affordable servicing. Whether you’re in Chennai, Pune, or Gurugram, we help you put automation to work — boosting output and product quality on your shop floor.

Conclusion

Pick and place robots do one thing very well — they move stuff. But that one task can change your shop floor. Faster output. Less damage. Safer workdays. Smoother shifts.

You don’t need to overhaul your whole plant. Start small. Maybe one robot on one conveyor. See the impact. Once you do, you might catch yourself wondering how you ever managed without them.