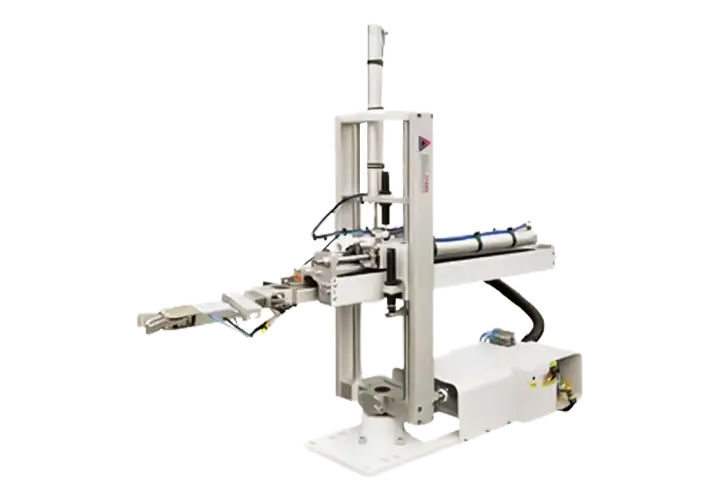

The plastic molding industry has grown dependent on precision, efficiency, and automation based on the incessant demand for high-quality products. One of the most significant yet lesser-known processes is the sprue picker. Also known as a sprue picker robot, it fulfills an important part in improving the efficiency of plastic molding in removing sprues. So let’s take a closer look at how these devices improve the molding process.

Also check the other products: Swing Arm Robots

Advantages of Using Sprue Pickers

Sprue pickers are valuable for molding operations due to the myriad advantages they bring with them.

First and foremost, they significantly impact the efficiency of production. By automating sprue removal, the robots reduce cycle time and permit the continuous running of molding machines

Second, sprue pickers yield high-quality functionality for the products produced. A sprue-picker robot reduces the risk of inconsistency and makes sure the sprue is removed uniformly.

Another major advantage is capitalisation. By eliminating human labour costs and minimizing wastage, sprue pickers make it profitable for a manufacturer.

Sprue pickers ultimately make for optimal space utilisation. These compact robots can occupy very tight spaces and clear floors for other manufacturing operations.

Key Features to Consider in Sprue Picker Selection

While selecting a sprue picker, some aspects must be taken into account.

- Payload Capacity: Ensure that the sprue picker robot can accommodate the weights of the sprues and runners from the molding process. An overloaded sprue picker risks impeding operations and causing damage.

- Speed and Accuracy: The speed of the sprue picker must match the cycle time of the molding machine. It must also be accurate enough to handle delicate components.

- Level of Automation: Modern sprue pickers robots come in different levels of automation. Choose a robot that will integrate with your automation goals.

- Ease of Integration: Pick a sprue picker robot that meshes well with your existing equipment. It must be compatible with the controls of your molding machine for its efficient and reliable performance.

- Maintenance and Durability: The best sprue pickers will be made of strong materials with minimal maintenance requirements. In this way, they promise reliability in the long run.

Challenges in Using Sprue Pickers

One common challenge includes the initial costs associated with these machines. Often, sprue picker robots are extraordinarily pricey such that investment in them becomes a challenge for small players. Nevertheless, when all factors are considered, the long-term cost savings in many industries lessen the impulse to avoid purchasing them.

Another challenge would involve the learning curve for programming and then for running these sprue pickers. Employees might have to undergo training to use this technology properly, and slow production might result during the period of adaptation.

Maintenance also poses an additional challenge if the sprue picker is not that great or spare parts are not available easily. Creating regular maintenance schedules along with selecting trustworthy manufacturers can lessen these problems.

Finally, integrating a sprue picker into an existing system is difficult if other machines, particularly older equipment, are in place. Because of compatibility problems, further additions may have to occur before the new machine can easily run in sync with the entire unit.

Choosing the Right Sprue Picker for Your Needs

The selection of the best sprue picker robot for your operation starts with assessing the specific requirements of your operation.

Review the various types of molded parts produced, the size and weight of the sprue, and much more. This way, you will narrow down many of the specifications that the sprue picker needs to meet.

On the other hand, speaking with some reputable suppliers or manufacturers of sprue-picking robots is also an important step. They could provide you with expert advice on what kind of model is appropriate for your setup.

Also, keep in mind the expectations for the production in the long run as you grow your production, hoping for further automation. Select a sprue picker with expandable features. If you invest in some dynamic robots, they could save money in the future.

Finally, analyse the economic efficiencies-the first cost against any labor, time, or material scrap costs saved. Get a good balance between quality and price, and you should be making a wise investment.

Bottom Line

Choosing the suitable sprue is dependent on understanding your production requirements, understanding the key features, and addressing challenges. While the initial investment seems high, the savings over the long term clearly outweigh the price involved. Regardless of the small or big setup that a sprue picker is installed into, adopting it would achieve a levelled-off process in the long run. With the right selection and maintenance, it could change perceptions regarding the handling of plastic molding and ensure consistent, reliable results.