Manufacturing and industrial models have advanced by leaps and bounds over the years. Manufacturing nowadays is distinguished by mass production, high efficiency, and the utilization of high-speed machinery. With the requirement to handle and move massive, heavy industrial and agricultural products, mechanical devices like conveyor belt became necessary to move the things with the least effort.

Belt conveyor systems are important in helping manufacturing and delivery processes. However, verifying that the systems function well and maintain the numerous operations is critical. It involves training personnel to avoid, troubleshoot, and fix problems. And today, we will tell you all about what is conveyor belt how it works and the benefits of Belt Conveyors! So, let’s get started!

Also Check out the Blog: Safety Measures of Belt Conveyors

What is a Conveyor Belt System?

A conveyor belt system is a mechanical handling device that transports things from one location to another quickly and efficiently. Conveyor systems come in various configurations, but all involve a frame holding a pair of wheels, conveyor rollers, or a belt. Materials are placed on top to be moved from one location to another. A conveyor belt can be propelled manually, by gravity, or, more typically, by a motor. There are several types of conveyor belt systems, each designed to carry out certain tasks.

How Conveyor Belts Work?

Belt conveyors or Chain conveyors are a material handling system that transports objects from one location to another using an unending belt. A belt conveyor system’s components are the pulley, the belt, and the motor that powers it. Belt conveyors operate on a simple principle: a motor powers an idler pulley, which causes the pulley to move the length of the belt. Friction between the idler pulley and the underside of the conveyor’s moving surface generates the force that propels the conveyor. This strong frictional force is responsible for movement in both directions along a given track. Conveyor belt systems’ major components are their supporting structure, driving mechanism, and loading device; these components work together to provide an efficient transportation system.

The supporting structure acts as a platform for all other components and must be built to withstand maximum loads while retaining its shape during operation. On top of this support are two major components: the driving mechanism, which uses motors and gearboxes to push or pull things down the track, and a loading device, which allows operators to load materials onto or off of belts simply. If the objects are exceptionally heavy or bulky, or if the conveyor belt is moving them long distances, rollers may be put on the conveyor belt’s sides for support.

Check out the common conveyor belt problems and how they can be fixed.

Types of Conveyor Belt Systems

To truly understand how conveyor belts function, it’s essential to look at the different types of systems available and their specific use cases.

1. Flat Belt Conveyors

Used for general material handling, flat belts are commonly seen in warehouses and distribution centres. They’re ideal for transporting packaged goods or irregular items.

2. Modular Belt Conveyors

Made of interlocking plastic pieces, modular belts are perfect for applications that require frequent cleaning, like food and pharmaceutical industries.

3. Cleated Belt Conveyors

With vertical cleats attached, these are used to transport materials up inclines and prevent rollback of items.

4. Incline/Decline Belt Conveyors

Designed to carry products to different elevations without the need for manual lifting.

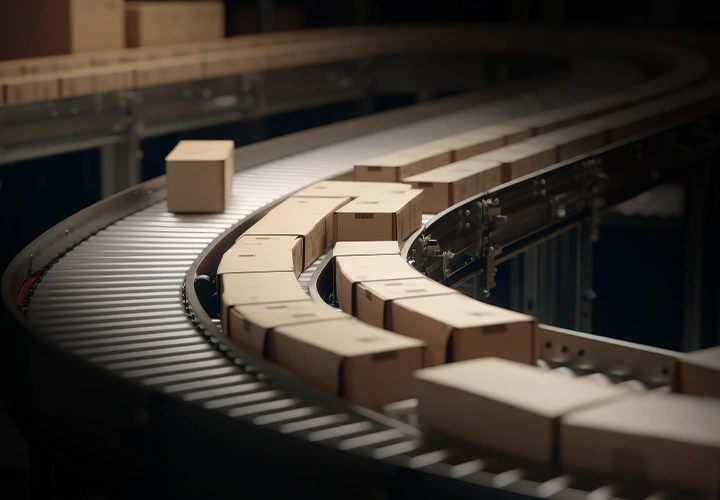

5. Curved Belt Conveyors

These help navigate floor layouts with limited space, moving goods around corners or obstacles efficiently.

How do Conveyor Systems Help?

Now, let’s talk about the benefits of Belt Conveyors. It takes longer, costs more, and raises the risk of physical injury when individuals transport large objects. Industrial conveyor systems move items more quickly. They can effectively move objects from one floor to another by spanning numerous floors. Conveyor belts can also automatically discharge commodities, removing the need for a worker to stand at the end of the line to offload the products.

Lightweight and heavyweight belt conveyors have various uses and applications in various situations and industries. Conveyor belt systems, whether light-duty or heavy-duty, have a remarkable potential to affect efficiency, production, and labor. Conveyors come in various shapes and sizes, each designed to fulfill a specific purpose. In addition to the most common belt and roller conveyors, alternatives include Magnetic, Vacuum, Wheel, Slat conveyors, and many more!

Bottom Line

Conveyor belts are crucial to many corporate processes, so selecting the right type is critical. Understanding the many types available and how they work can assist you in making an educated selection and ensuring that your operation operates smoothly and efficiently. And if you seek help with your conveyor belts, contact Delta Stark. We are a leading manufacturer of belt conveyors, and our knowledgeable team can help you find the best solution for your company’s goals and budget.