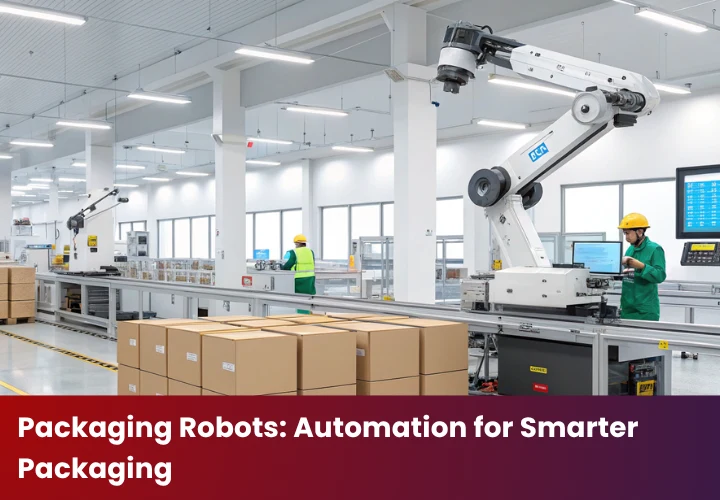

The packaging industry is fast-paced, ever-changing, and competitive today. As manufacturers adopt robotics, packaging robotics also gears up in speed, aiming for accuracy and quality. With the aid of AI in packaging automation, these robots are being used extensively for packing, sealing, and shipping products. Let’s see how these intelligent machines are being given that edge.

What Are Packaging Robots?

Packaging robots are machines meant to automate the packaging of products. Their functions include pick and place, boxing, labelling, condemning, and palletising. Depending on the task at hand, these machines can be robotic arms, delta robots, or collaborative robots (cobots). Working together with AI-based packaging automation, these robots are faster and more precise than ever before.

Benefits of Automation in Packaging

Use of robotics in manufacturing comes as a blessing in disguise for the packaging process:

- Performance of Speed: Able to perform the same work as humans with speed and without breaks.

- Consistency and Accuracy: They reduce human error and ensure uniformity in packaging from one product to another.

- Cost Savings: Although the initial setup of the machinery may be expensive, it has been proven over time that robots require less labour and waste fewer materials.

- Safety: Packaging robots allow workers to avoid repetitive and hazardous tasks.

- Scalability: Robots allow businesses to scale operations quickly, making it easy to meet high demand.

Key Features of Modern Packaging Robots

Modern packaging robots are not just simple machines. They have smart features that make them highly effective:

- Vision Systems: This helps robots identify products of different shapes and sizes.

- AI Integration: AI in packaging automation enables robots to learn and develop through experience in order to improve.

- Flexibility: Robots can be reprogrammed to do whatever they might be needed for with different tasks or new product lines.

- User-Friendly Controls: Many packaging robots are provided with simple-to-operate user interfaces, which are helpful for workers who are not expert operators.

Industries That Benefit Most from Packaging Robots

Packaging robots have seen major improvements in several industries:

- Food and Beverage: Rapid packaging of perishable goods while maintaining hygienic conditions.

- Pharmaceutical: Sterile packaging with rigorous control on safety and quality.

- E-commerce and Retail: Payment for orders first, and packaging second. Electronics: Careful handling of delicate items and packaging of the same.

- In manufacturing, pickup and place robots thus enhance productivity and maintain standards.

How Packaging Robots Enhance Sustainability

With sustainability becoming more and more important, robots are needed more in packaging:

- Less Waste: More efficient use of materials, hence limiting wasteful packaging.

- Energy Conservation: New robots consume less energy.

- Optimisation of Packaging: AI methods implement optimal packaging solutions with fewer resources.

Thus, by revolutionising packaging, robots sustain the Earth and offer an improved experience to the end customers.

Challenges and Considerations

- High Initial Costs: A huge amount of capital is required for investing in robotics.

- Training Needs: Responsible personnel will require training to perform the maintenance and operation of the systems

- System Integration: Accurate engineering integration is needed to ease workflows and processes.

- Maintenance: Regular maintenance is required to ensure that it does not break down or cause downtime.

Future Trends in Packaging Automation

The trends in packaging robot applications are extremely promising and exciting:

Smarter AI: The AI will get smarter and is expected to predict faults before they occur.

Collaborative Robots (Cobots): Cobots and humans will share the company, thus improving collaboration and efficiency.

Smaller Footprint Machines: Compact designs will allow robots to be integrated into more spaces.

Cloud Connectivity: Real-time data and remote monitoring will improve performance and maintenance.

With changing AI in packaging automation, we can expect packaging systems to get smart, green and fast.

Types of Packaging Robots Used in Industries

Not all packaging robots are the same—different industries require specialized robots depending on product type, speed, and precision. Here are the most common types:

1. Pick and Place Robots

Widely used in food, pharma, and e-commerce, these robots quickly pick products and place them into cartons, trays, or conveyor belts with high accuracy.

3. Palletising Robots

Designed to stack boxes, bags, or cartons on pallets. They reduce manual labour and streamline end-of-line packaging operations.

3. Delta Robots

Known for speed, these lightweight robots are used in high-volume packaging lines, especially in FMCG and confectionery industries.

4. Collaborative Robots (Cobots)

Safe to work alongside humans, cobots assist in packaging where space is limited and flexibility is essential.

5. Carton Loading & Sealing Robots

These specialised packaging robots handle tasks like carton erecting, filling, and sealing—ideal for retail and e-commerce businesses.

By choosing the right type of packaging robot, businesses can optimise productivity, reduce costs, and maintain quality standards consistently.

Conclusion

Packaging robots are changing the way industries pack and ship products. With the power of robotics in manufacturing and smart AI in packaging automation, companies can attain higher efficiencies, consistency, and sustainability. Whilst with certain initial hurdles to be faced, the rewards payable in the long term for investment are worth it. Packaging will continue to grow smarter with time, and robots will lead the way.